—— news ——

With the continuous development of the mechanical automation industry, various new motor technologies are also emerging. Among them, linear servo motor, as a new type of motor technology, is widely used in the mechanical automation industry. This article will explore the principles, characteristics, and applications of linear servo motors in the mechanical automation industry.

1、 The principle of linear servo motor

Linear servo motor is a type of motor that controls motion through electrical signals, and its working principle is basically the same as traditional rotary servo motors. It mainly consists of motors, sensors, controllers, etc. The motor part of a linear servo motor is composed of a magnetic slider and a coil. When current passes through the coil, a magnetic field is generated on the magnetic slider, causing it to move in the direction of the coil. The sensor part of the linear servo motor is composed of a set of photoelectric encoders and a feedback circuit. The photoelectric encoder can accurately measure the position of the magnetic slider, and the feedback circuit can feedback the measured position information to the controller. The controller controls the magnitude and direction of the current based on feedback information, thereby achieving motion control of the linear servo motor.

2、 Characteristics of linear servo motors

High precision: The linear servo motor uses high-precision sensors and feedback circuits to achieve precise position control, and its accuracy can reach the micrometer level.

High speed: The response speed of the linear servo motor is very fast, which can achieve high-speed motion and fast switching.

High efficiency: The efficiency of linear servo motors is higher than that of traditional motors because they do not require a power transfer mechanism, thereby reducing energy loss.

High reliability: The linear servo motor has a simple structure and no friction parts or mechanical transmission, thereby reducing the possibility of mechanical failures.

3、 The Application of Linear Servo Motor in the Mechanical Automation Industry

Machine tool processing: Linear servo motors can be used to control the feed axis and spindle of machine tools, achieving high-precision and high-speed processing.

Printing machinery: Linear servo motors can be used to control the paper feed and output shafts of printing machines, achieving high-speed and high-precision printing.

Packaging machinery: Linear servo motors can be used to control the feeding and sealing shafts of packaging machines, achieving high-speed and high-precision packaging.

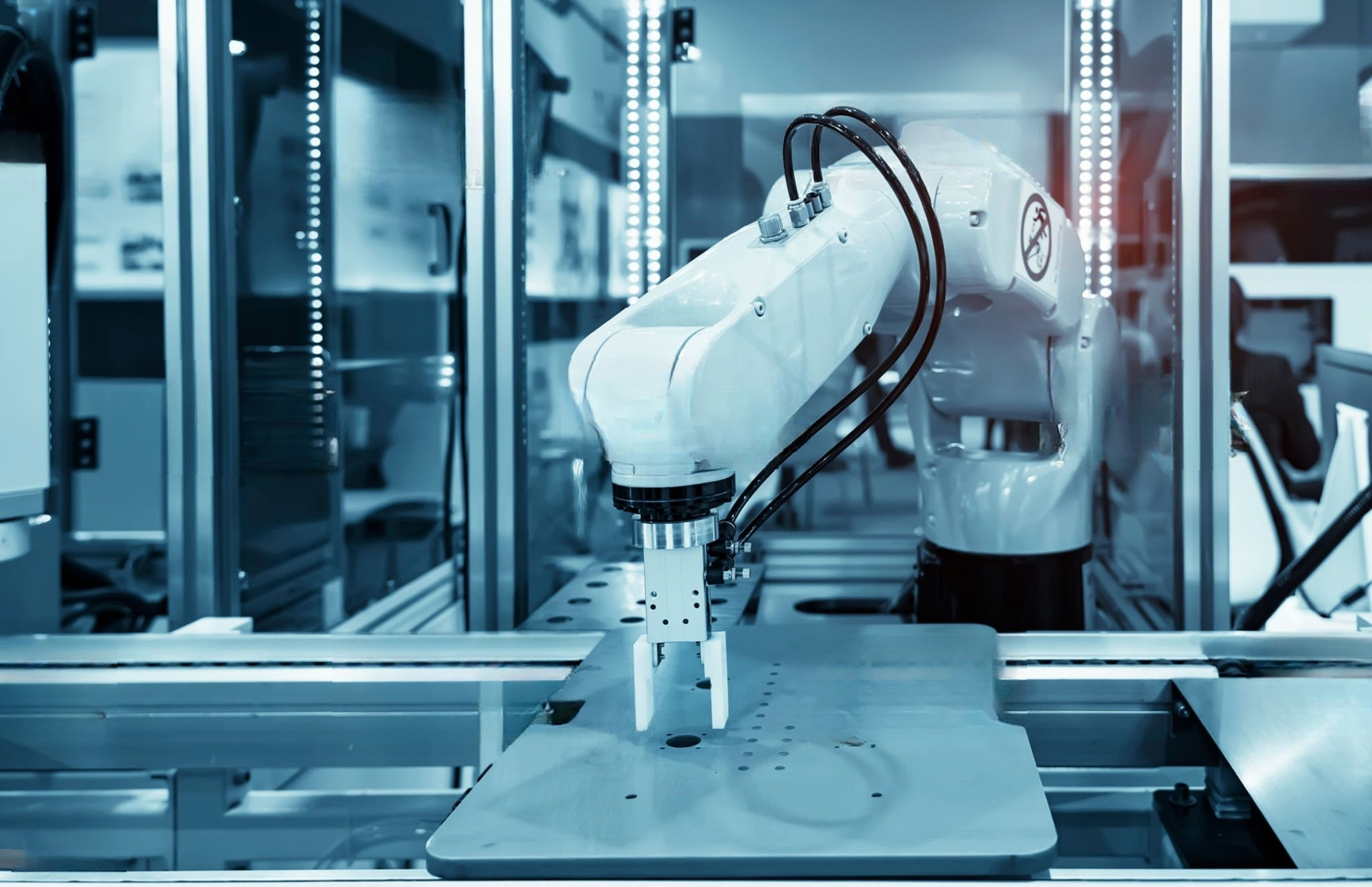

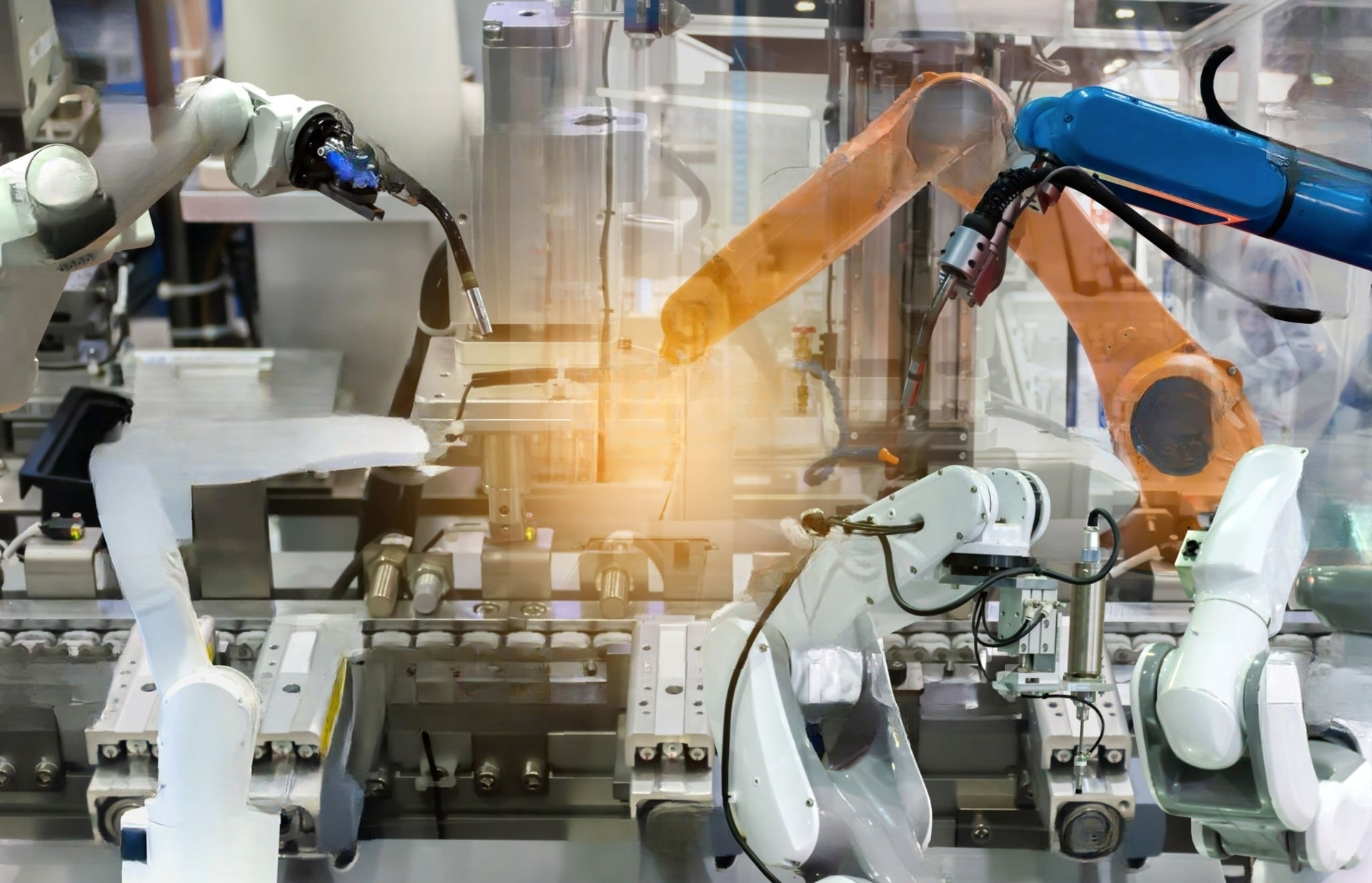

Automated production line: Linear servo motors can be used to control various conveyor belts, conveyors, robotic arms, etc. on automated production lines, achieving efficient and high-precision automated production.

In summary, linear servo motors, as a new type of motor technology, have broad application prospects in the mechanical automation industry. Its high precision, speed, efficiency, and reliability make it an important component of the mechanical automation industry, injecting new vitality into its development.

Company Contact Information

Head Factory (Korea Headquarters)

Address: 179, Seonan-ri, Eunhyun-Myeon,Yangju-city, Kyunggi-do Korea

Tel: +82-31-863-2801

E-mai: hnk@scmi21.com

Shanghai Factory(Shanghai factory)

Address : 1-2/F, Building F, No. 783

Shenglong Road, Jiuting Town,

Songjiang District, Shanghai

Tel: +86-21-5488-4842

Email: jihong.choi@outlook.kr

scmi79@163.com

scmi06@163.com

GREEN-ENCO

Request information